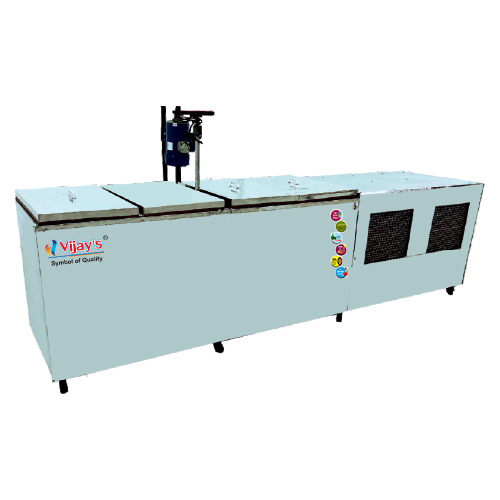

Smooth and consistent ice production depends heavily on how well the brine tank supports the freezing process. When ice blocks are formed through moulding systems, the brine tank becomes the core of temperature control, cycle timing, and overall plant efficiency. As one of the experienced brine tank manufacturers, we understand that selecting the right tank is not only about capacity, but also about performance reliability across long operating hours.

Ice block and ice moulding plants often operate in demanding environments where continuous cooling and precise temperature balance are essential. A well-designed brine tank ensures uniform freezing, minimizes ice cracks, and helps achieve faster mould release. All these factors affect the decision of choosing a brine tank as they are crucial for maintaining production quality and operating costs. If you are also planning to invest in brine tanks, then you must go through this blog.

Check the quality of the material used

Brine solutions used in ice moulding are highly saline and remain in constant contact with the tank surface. For this reason, material quality becomes one of the most essential features to check before purchasing. Always go for a brine tank that uses materials that can resist corrosion, surface erosion, and chemical reaction over extended periods of use. Use of strong material construction helps maintain the structural integrity of tanks and prevents issues such as leakage or surface damage. This ensures uninterrupted operation and supports long service life even when the system runs continuously during peak demand seasons.

Always check thermal insulation efficiency

Thermal insulation is quite helpful in maintaining a stable brine temperature throughout the freezing cycle. A brine tank with efficient insulation minimizes heat gain from the surrounding environment and helps retain low temperatures consistently. This stability allows ice moulds to freeze evenly without unnecessary strain on the refrigeration system. Good insulation also supports energy efficiency by reducing compressor load and preventing temperature fluctuations. Over time, this results in smoother ice moulding cycles and more predictable production output. Ice plants benefit from reduced power consumption and improved control over freezing duration.

Look for a proper brine circulation design

Effective brine circulation ensures uniform temperature distribution inside the tank. A well-designed circulation system allows brine to flow evenly around all ice moulds, preventing localized temperature variation. This helps achieve consistent freezing across the entire tank and reduces cycle time differences between moulds. Proper circulation also supports stable system performance during continuous operation. Balanced brine movement reduces stress on refrigeration components and helps maintain consistent freezing conditions over long production hours. Experienced brine tank manufacturers focus on circulation design because it directly impacts ice quality and operational reliability.

Check tank size and mould layout compatibility

The internal dimensions of a brine tank should be designed to suit the specific ice moulds used in the plant. Proper tank size ensures adequate spacing between moulds, allowing uniform brine contact on all sides. When moulds are positioned correctly, freezing remains consistent across batches, improving ice block clarity and strength. Compatibility between tank size and mould layout also simplifies handling during loading and unloading. Smooth movement of moulds reduces operational delays and minimizes the risk of physical damage during daily operations. Well-planned internal design supports better workflow and higher productivity.

Conclusion

When investing in the right brine tank for ice block and ice moulding systems, evaluating material strength, insulation efficiency, internal layout, and circulation design is essential. These features together determine how effectively the tank supports daily production and long-term performance. We at Vijay’s Energy Industries (India) Pvt. Ltd., being one of the best brine tank manufacturers, always focus on delivering brine tanks that meet ice plant requirements and support dependable, efficient ice production.